GMA pallets are the backbone of efficient logistics, ensuring smooth movement of goods across North America’s supply chains. In today’s fast-paced world, especially for food and consumer products, choosing the right pallet is more important than ever. This guide delivers the most up-to-date and comprehensive overview of GMA pallets for 2025, covering standards, grade classifications, key benefits, industry uses, and expert advice for making the best choice. Discover why GMA pallets are the gold standard in warehousing, how the right selection can boost safety, cost savings, and sustainability, and learn actionable tips to master pallet use in the year ahead.

What Are GMA Pallets? Definition and Evolution

GMA pallets are at the heart of modern logistics, especially in North America. These standardized platforms make the movement of goods smoother, safer, and more predictable for industries like food and consumer products. But what exactly are GMA pallets, and why have they become the gold standard in supply chains? Let’s explore their definition, evolution, and material options.

GMA Pallets Explained

GMA pallets, also known as “standard pallets” or “GMA 48×40,” are standardized 48-inches in length by 40-inch wide pallets first specified by the Grocery Manufacturers Association, now called the Consumer Brands Association (CBA). They are easily recognized by their 4-way forklift entry. Which means you can enter them from both the front and back of the pallet as well as from the sides. They are also known for their sturdy construction, typically from wood or plastic.

These pallets are everywhere in the U.S., with over 1.8 billion in circulation, and most of them follow the GMA standard. Their consistent size and design help streamline warehouse operations and logistics by ensuring compatibility with racking, forklifts, and automated systems. In fact, if you’ve ever seen food or household goods stocked in stores, chances are they arrived on GMA pallets. For a deeper dive into their features and uses, check out this GMA pallet overview.

Historical Development and Industry Adoption

The story of GMA pallets began in the 1920s, when the rise of forklifts created a need for more uniform platforms. During World War II, standardized pallets gained traction as the military searched for efficient ways to move supplies. After the war, the grocery and retail industries recognized the benefits of a common pallet size, leading the GMA to establish the 48×40 inch standard.

This move changed the game. Retail giants like Walmart and Costco adopted the GMA pallet, and its influence only grew as the Consumer Brands Association took over from the original GMA. Internationally, the GMA pallet is recognized by ISO as one of six global standard sizes, making it an essential part of cross-border logistics. Standardization has driven efficiency, safety, and seamless interoperability across entire supply chains.

Materials: Wood vs. Plastic GMA Pallets

GMA pallets come in two main materials: wood and plastic. Each offers unique advantages and is chosen based on specific application needs.

Wood GMA Pallets:

- Most common and cost-effective

- Easy to repair and recycle

- Quality can vary due to wood type and usage

Plastic GMA Pallets:

- Consistent quality, non-absorbent surface

- Ideal for food, pharmaceutical, and automated environments

- Higher upfront costs but can last up to 10 times longer than wood in some settings

Plastic GMA pallets are seeing rapid adoption in automated warehouses and food-grade applications, thanks to their durability and hygiene. In fact, many companies are switching to plastic for export and automation, while wood remains popular for general use due to its lower initial cost. The choice between materials depends on factors like lifespan, cleanliness, and specific industry requirements.

GMA Pallet Standards and Specifications (2025 Update)

Understanding the latest standards for GMA pallets is crucial for anyone involved in logistics, warehousing, or supply chain management. In 2025, both manufacturers and end-users rely on these updated guidelines to ensure seamless operations, consistent quality, and regulatory compliance.

Dimensional and Structural Standards

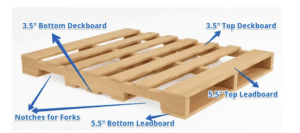

The backbone of GMA pallets is their precise dimensional and structural specifications. The standard size remains 48 inches by 40 inches, with a typical height of 6.5 inches. This universal sizing allows GMA pallets to fit effortlessly into storage racks, trucks, and automated systems.

Here is a quick overview:

| Feature | Specification |

|---|---|

| Length x Width: | 48” x 40” |

| Height: | 6.5” |

| Load Capacity (Wood): | Minimum 2,500 lbs |

| Load Capacity (Plastic): | Up to 4,000 lbs |

| Top Deck Boards: | 7 (1x 5.5” + 5x 3.5” + 1x 5.5”) |

| Bottom Deck Boards: | 5 |

| Forklift Entry: | 4-way (notched stringers) |

| Board Thickness: | Minimum 0.5” |

Major suppliers like PalletOne and iGPS strictly adhere to these specifications for their GMA pallets product lines. The consistent construction ensures pallets can handle heavy loads without warping or breaking. Four-way forklift entry provides flexible handling options, speeding up loading and unloading processes.

This level of standardization is what makes GMA pallets compatible with virtually all warehouse racking and conveyor systems. As automation becomes more common, having precise and predictable pallet dimensions is more important than ever.

Grading System: Premium, Grade A, B, and C

Not all GMA pallets are created equal. The industry uses a grading system to classify pallets by condition, repair history, and suitability for various applications. Understanding these grades helps companies choose the right pallet for their needs and budget.

Here’s a breakdown of the grading system:

- Premium: Like-new, with little or no repairs. These GMA pallets have consistent appearance and structure, ideal for retail or display.

- Grade A (or #1): Lightly used, may have minor repairs but remain structurally sound. A popular choice for food and consumer goods shipping.

- Grade B (or #2): More repairs, such as companion stringers or replaced deck boards. These GMA pallets often show visible wear but are still functional for non-retail or warehouse uses.

- Grade C (or #3): Heavily repaired, multiple stringer fixes, and often near the end of their usable life. Typically not accepted for critical loads or export.

Grading criteria include:

- Number and type of repairs

- Condition of deck boards and stringers

- Cleanliness and overall appearance

For a deeper dive into these classifications and their industry impact, see this comprehensive resource on GMA pallet specifications and grades.

Choosing the appropriate grade affects cost, safety, and compliance. Many companies now avoid Grade C GMA pallets entirely due to increased risk of failure and safety concerns.

Compliance and Certification Requirements

With GMA pallets in widespread use, meeting compliance standards is non-negotiable. For international shipping, heat treatment to ISPM 15 standards is required to prevent pest transmission. This certification is a must for any pallet crossing borders.

In food and pharmaceutical supply chains, plastic GMA pallets or heat-treated wood versions are standard for hygiene and regulatory reasons. Certification from recognized bodies such as the Consumer Brands Association (CBA), ISO, and third-party auditors provides assurance your pallets meet all safety and tracking requirements.

Traceability has become increasingly important. Modern GMA pallets often come with unique identifiers or barcodes to support recall management and supply chain transparency.

Innovations and 2025 Trends in GMA Pallets

As the industry evolves, GMA pallets are seeing several key innovations. Automation compatibility is driving demand for pallets with precise sizing, embedded RFID tags, and consistent construction. Many distribution centers are investing in plastic GMA pallets for their durability and ease of cleaning, especially in food and pharmaceutical sectors.

Sustainability is also a top trend. Companies are adopting recycled materials, buy-back programs, and reusable plastic options to reduce environmental impact. Enhanced hygiene features, such as non-absorbent surfaces, are now standard in pallets for sensitive goods.

With real-time tracking and automation on the rise, GMA pallets are more essential—and more advanced—than ever.

Key Benefits of GMA Pallets

GMA pallets offer key advantages that make them the backbone of American logistics. Their standardized design, safety features, sustainability benefits, and cost efficiency drive their widespread use across multiple industries. Let’s explore why gma pallets remain the preferred choice for supply chain professionals in 2025.

Standardization and Supply Chain Efficiency

The standardized 48×40 size of GMA pallets ensures universal compatibility with racking, forklifts, and automated systems. This consistency streamlines warehouse operations, making loading and unloading faster and reducing costly handling errors.

Using gma pallets means products move smoothly through every stage of the supply chain. Pallet pooling and exchange programs become possible, eliminating the headaches of mismatched sizes. According to industry data, standardization can reduce supply chain costs by up to 20 percent. Non-standard pallets, in contrast, often create bottlenecks, increase labor, and slow down shipments.

For a deeper understanding of how standard sizes and specifications impact efficiency, see GMA pallets: sizes and specifications.

GMA pallets are essential for just-in-time inventory systems, helping companies keep shelves stocked and operations running smoothly.

Safety and Product Protection

Uniform construction of gma pallets reduces the risk of tipping and shifting during transport. Consistent load capacities make safe stacking possible, protecting goods from damage.

Workplace safety also improves with gma pallets. Predictable handling means fewer injuries on the warehouse floor. Automated systems rely on standardized pallets to operate safely and efficiently, keeping both products and people secure.

Sustainability and Environmental Impact

Gma pallets contribute to sustainability goals in several ways. Wood pallets are recyclable, repairable, and biodegradable, reducing their impact on landfills. Plastic varieties are reusable and recyclable, with a lower lifetime carbon footprint.

Many brands participate in buy-back and recycling programs, further minimizing waste. In fact, up to 95 percent of wood gma pallets are recycled annually in the United States, making them a smart choice for eco-conscious businesses.

Cost Savings and Longevity

Gma pallets deliver cost savings throughout their lifecycle. Their repairability and reusability lower the total cost of ownership. Companies benefit from bulk purchasing and pooling, which reduces per-pallet expenses.

Plastic gma pallets, while more expensive upfront, offer a longer lifespan that offsets initial investments. Grade B pallets provide a budget-friendly option for non-retail uses, allowing businesses to balance cost and performance. Investing in quality gma pallets helps minimize replacement costs and operational downtime.

Versatility Across Industries

Gma pallets are used in food, beverage, pharmaceuticals, retail, and manufacturing. Their adaptable design supports a wide variety of products and supply chain needs. Whether moving perishables or non-perishables, gma pallets remain the go-to choice for reliable, efficient transport.

Common Uses and Industry Applications

GMA pallets are essential to modern logistics, supporting supply chains across multiple sectors. Their standardization enables seamless movement of goods, while their versatility means they are used far beyond grocery stores. Let’s look at the top ways industries rely on GMA pallets today.

Food and Grocery Distribution

In the food industry, GMA pallets are the default choice for moving products from farms to shelves. Their consistent size and construction help meet FDA and FSMA requirements for food safety. Supermarkets, distributors, and manufacturers use GMA pallets to keep perishable and packaged goods moving efficiently.

For example, PalletOne’s whitewood GMA pallets are a staple in supermarket supply chains. The reliability of GMA pallets ensures that food products arrive safely and on time, minimizing spoilage and delays. Their compatibility with automated systems also supports rapid sorting and distribution.

Manufacturing and Warehousing

Manufacturers and warehouses depend on GMA pallets for smooth operations. These pallets are compatible with automated storage and retrieval systems, as well as robotic palletizers and conveyors. Industries like automotive and electronics trust GMA pallets for handling parts, finished goods, and raw materials.

Over 90 percent of U.S. warehouses use GMA pallets for general storage, highlighting their dominance. The standardized design reduces the risk of equipment jams and handling errors, supporting efficient workflows and reducing costs. GMA pallets also facilitate pallet pooling and exchange programs across facilities.

Pharmaceutical and Clean Industries

For pharmaceuticals and other clean industries, GMA pallets made from plastic are often preferred. These pallets are non-absorbent and easy to sanitize, which is critical for minimizing contamination risks. Medical device manufacturers and drug companies rely on GMA pallets when shipping sensitive items.

FDA-regulated facilities frequently require plastic or heat-treated GMA pallets to ensure compliance. The consistent quality and hygiene standards of GMA pallets help organizations meet strict regulatory requirements. Using the right pallet helps maintain product integrity and safety throughout the supply chain.

Export and International Shipping

Exporters must meet international shipping standards, and GMA pallets play a central role in this process. For cross-border shipments, pallets must be ISPM 15 certified to prevent pest transmission and avoid costly delays. Many companies choose heat-treated or plastic GMA pallets for global acceptance.

To ensure compliance, exporters often source Heat Treated GMA Pallets for Export that meet all relevant standards. Non-compliant pallets can lead to rejections or quarantines at ports, so using certified GMA pallets is a must for hassle-free international logistics.

Retail and Point-of-Sale Displays

Retailers use premium and Grade A GMA pallets for in-store displays and product presentation. These pallets offer a clean, uniform look that enhances the shopping experience and supports brand image. Club stores like Costco and Sam’s Club require GMA pallets that are display-ready and meet strict specifications.

Retailers set high standards for the pallets they use on the sales floor, ensuring safety and visual appeal. GMA pallets’ reliability means they are trusted for both perishable and non-perishable goods, from beverages to household products. Their versatility supports a wide range of retail applications.

How to Choose the Right GMA Pallet for Your Needs

Selecting the right gma pallets for your business can make a significant impact on your supply chain efficiency and costs. With so many options and requirements, knowing what to look for is the first step toward making a smart, future-proof choice.

Assessing Application Requirements

Start by identifying the specific needs of your operation. What type of products will be shipped on your gma pallets? Consider the weight and dimensions of your goods, as well as how the pallets will be handled throughout the supply chain.

If you are in the food or pharmaceutical industries, compliance is essential. Gma pallets used for perishables or regulated products often need to be heat-treated or made of plastic for extra hygiene. For dry goods or less sensitive items, standard wood pallets may suffice.

Assess the handling environment too. Will your gma pallets be used in automated warehouses, exposed to moisture, or stacked high? Answering these questions narrows your options and ensures both safety and efficiency.

Deciding Between Wood and Plastic

The choice between wood and plastic gma pallets depends on your priorities. Wood pallets are widely available, cost-effective, and recyclable. They work well for general warehousing, shipping, and less demanding environments.

Plastic gma pallets, on the other hand, offer consistent quality, are non-absorbent, and excel in hygienic or automated settings. They are ideal for food, pharma, and export. While the upfront cost is higher, their durability and long lifespan provide value over time. For specialized needs, explore plastic pallets for food and pharma to meet strict industry standards.

Compare your handling needs, budget, and regulatory requirements before making a decision. The right material choice can streamline your operation and reduce long-term costs.

Understanding Grading and Quality

Gma pallets come in several grades, each suited for different uses. Premium and Grade A pallets are clean, strong, and have minimal repairs, making them perfect for retail displays or sensitive shipments. Grade B pallets show some repairs but remain structurally sound, ideal for warehousing and internal use.

Avoid Grade C pallets for critical loads, as their multiple repairs and visible wear can pose risks. Always inspect for cleanliness, repairs, and certification marks to ensure safety and compliance.

Understanding the grading system helps you match the right gma pallets to your application, balancing cost, appearance, and durability for optimal performance.

Sourcing and Supplier Considerations

Choosing a reputable supplier is key to maintaining supply chain reliability. Look for providers who:

- Offer transparent grading and certification

- Provide customization options for your gma pallets

- Support buy-back and recycling programs

- Ensure traceability for quality assurance

Suppliers like PalletOne and iGPS are known for compliance and transparency. If you need new, standardized options, check out new 48×40 GMA pallets for sale. Reliable sourcing minimizes the risk of disruptions and helps maintain consistent quality throughout your operations.

Cost, Sustainability, and Lifecycle Analysis

Evaluate the total cost of ownership for your gma pallets. Factor in purchase price, repair costs, and the potential for recycling or resale. Wood pallets are affordable upfront and easy to repair, while plastic pallets offer lower long-term costs due to their durability and reusability.

Consider environmental impacts as well. Many companies now choose recycled-content gma pallets to meet sustainability goals. Lifecycle analysis can reveal that sustainable choices often align with cost savings.

Making informed decisions about gma pallets ensures your business stays efficient, compliant, and environmentally responsible for years to come.

FAQs and Expert Tips on GMA Pallets

Frequently Asked Questions

When it comes to gma pallets, there are plenty of common questions that come up. If you’re looking for clear, direct answers, you’re in the right place. Here are some of the top questions businesses ask about gma pallets today:

What does “GMA” stand for, and who sets the standards?

GMA stands for Grocery Manufacturers Association, now known as the Consumer Brands Association (CBA). The CBA, along with industry partners, maintains the specifications for gma pallets.Are gma pallets only used for groceries?

No, gma pallets are used across food, beverage, retail, manufacturing, and even pharmaceuticals. Their standard size and quality make them a top choice in many industries.How are gma pallets graded, and what do the grades mean?

GMA pallets are graded as Premium, Grade A, Grade B, or Grade C, based on repairs, wear, and structural integrity. Higher grades mean better condition and suitability for sensitive applications.Can gma pallets be used for export?

Yes, as long as they meet ISPM 15 heat treatment standards for wood or are made of export-compliant plastic. This ensures they are accepted at international ports.What’s the difference between white wood and rental pool pallets?

White wood pallets are typically single-use or recycled wood, while rental pool pallets are managed, tracked, and maintained by a pallet pooling company for consistent quality.Are plastic gma pallets really worth the higher cost?

For sectors requiring top hygiene, durability, or automation compatibility, plastic gma pallets often provide a better long-term value despite higher upfront costs.How often should gma pallets be inspected or replaced?

Regular inspections should occur at each use cycle. Replace pallets with major cracks, broken boards, or failed repairs to maintain safety and compliance.

For even more in-depth answers, check out this GMA Pallet FAQs and Answers resource.

Pro Tips for Maximizing GMA Pallet Value

Getting the most from your gma pallets is all about smart management and a proactive approach. Use these expert strategies to boost efficiency and reduce costs:

Inspect and repair regularly:

Routine checks catch issues early, extending the lifespan of your gma pallets and preventing safety risks.Match the grade to your needs:

Use Premium or Grade A for retail and food, Grade B for warehousing, and avoid Grade C for heavy or sensitive loads.Implement pooling programs:

Participate in pallet pooling to lower upfront expenses, reduce storage needs, and ensure a steady supply of quality gma pallets.Track pallets with technology:

Use RFID tags or barcodes to monitor pallet location, prevent loss, and streamline inventory management.Partner for recycling and buy-back:

Choose suppliers who offer recycling or buy-back programs. This supports sustainability and can provide cost savings over time.

Retailers with automated warehouses require undamaged, precise gma pallets for smooth operations. By following these tips, you’ll minimize downtime, improve safety, and keep your supply chain moving efficiently.